|

MSS Sand Screen Co., Ltd

|

Slotted liner customized slot width

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Slotted liner is used in long horizontal completions or low productivity wells where gravel packed or sand is large. Clogging problem is greatly decre

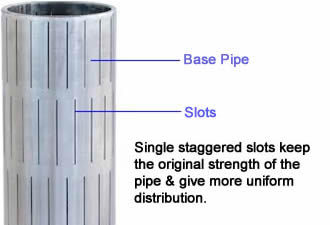

Slotted liner or standalone screen is a popular sand control screen in long horizontal completions and low productivity wells. Precision slotted liners are manufactured by CNC controlled slotting machines or laser machine. All slots are de-burred, cleaned and drift tested according to API standards. Base pipe are per API casing or tubing specification with diameters from 1.5 inch to 18 inch. Pipe lengths of any diameter are available.

Slot size

Slot size including slot width and length is customized to suit customer's requirement. For straight or keystone slots, minimum slot width is 0.012 inch and maximum slot width would be 0.25 inch.

1.5 inch long2.0 to 2.5 inch long2.5 inch long

| 0.012 inch wide | 0.024 inch wide | 0.078 inch wide |

| 0.015 inch wide | 0.025 inch wide | 0.125 inch wide |

| 0.016 inch wide | 0.038 inch wide | 0.250 inch wide |

| 0.018 inch wide | 0.048 inch wide | - |

| - | 0.058 inch wide | - |

Slotting pattern

Slot Pattern

A: refers to single staggered slots.

B: refers to straight slots.

C: refers to multiple staggered slots.

Slot Shape

Slot shape

Straight slot

Straight slot has straight sides with equal width through the wall of the casing. It is normally used in consolidated formations or when slots of 0.030" or wider are specified.

Pros: Higher resistance to wear and more economical than keystone.

Cons: The possibility of clogging is higher than keystone slot.

Keystone slot

Keystone slot is like a reversed "V" with narrower spacing at the liner surface and wider spacing in the inside casing wall. This shape allows for sand grains to bridge across the opening and ensures all the particles that enter into the hole will completely go through the wall.

Pros: Keystone shaped slots substantially reduce the possibility of clogging and improve work efficiency.

Cons: A little expensive than straight slotted liner.

Applications:

Slotted liners are suitable for gravel packed completions or stand-alone completion where grain size is large.

How many holes needed to achieve a certain open area?

N =

N = the number of slots per foot.

D = Outside diameter of the liner (in inches).

C = Open area percentage.

W = selected slot width (in inches).

L = Length of slot (inches).